Many PCB manufacturers offer good quality PCBs for a low price. Anyway, there may be lots of small things that may lead to a few inconveniences if your choice isn’t the best. Of course, the primary source to check out is the Internet. Customer feedback may be a good starting point to evaluate the PCB manufacturing process of the chosen vendor. Other sources worth checking are the social media, colleague recommendations, or other influences. Sometimes there is nothing wrong with trying any manufacturer with some small batch and evaluating PCB manufacturing process and building quality by yourself. There may be a different experiences for different people, and what is bad for one may be suitable for others.

Evaluating the quality of delivered PCB

If you decided to try a new PCB manufacturer, there are some key points that you may want to check when boards are received. Most of them are PCB quality checks. You may go through several aspects, such as:

- Dimensions of the board – are they right as specified

- The holes – are dimensions correct and accurately positioned and centered

- Cutting quality – inspect the edges of boards are they properly cut

- Silkscreen – are they readable and small parts visible

- Solder mask – is it accurate and well positioned

- Are connectivity tested? – most manufacturers already perform.

These are small and basic things that may influence the choice of PCB manufacturer. The PCB quality is the key to a successful build of the electronic device.

Design your PCB while keeping an eye on manufacturer requirements

Before you build a new PCB board, it is good practice to check the conditions of the selected manufacturer. They usually specify the minimum and maximum sizes of PCB parts, such as holes, traces, dimensions, clearings, etc. If they determine the most diminutive possible dimensions, it doesn’t mean that you should try to squeeze to smallest. With small sizes, there is always a risk of increased failures. Use common sense, which comes with practice.

The other factors in choosing the right PCB manufacturer

The manufacturing cost. It may be an essential factor in some cases, but competing PCB manufacturers keep prices close to each other. The other factors may be more important such as timescale – the time it takes to manufacture a PCB. If you need boards fast, then it is an essential factor. Of course, then follows the delivery, which can be sometimes frustrating. Be sure to check possible delivery options and prices. The other factors may be some bonuses, such as the number of boards included when ordering one, discounts, coupons and others.

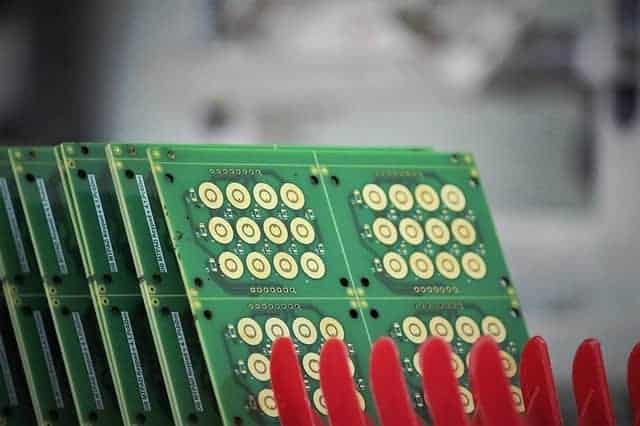

In general, you should look for a PCB manufacturer that fits your needs. If not, then try matching manufacturer capabilities to your needs. Selecting the proper manufacturer is an essential step toward successful electronic equipment assembly and production. Time spent on choosing PCB manufacturer is well spent and can be a significant factor in the long term. If you are planning a large batch of PCBs, it is worth visiting the company and seeing the whole process of making quality boards.