Industrial robots have a place in the automotive industry, but it took tens of years to get where they are today. Most basic robotic ideas go as far back as Leonardo da Vinci. The modern robot, as we know it, emerged in a play in 1921. The robots in this play were mechanical beings who were human helpers but later revolted and took control of the world. This was certainly not a very good start for robots, but things and mentalities have changed over the years.

The automotive industry took time to adapt to robotic technology, but there was no going back once it did. Robots are a significant contributor to the automotive industry in different capacities. Here are some of the most common robotic applications:

Robotic Vision

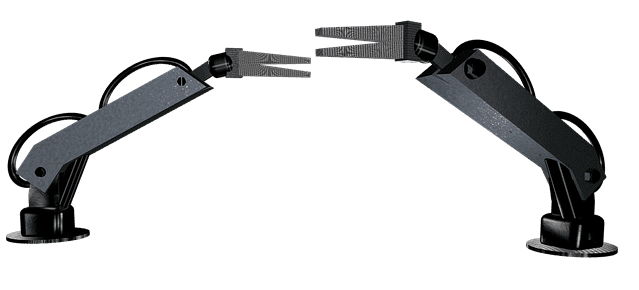

Light industrial robotic arms with ‘vision’ do a more precise job because it ‘sees’ what it is doing. The robot’s wrist has lasers and cameras that provide the machine with immediate feedback. Robots can perform offsetting when installing parts because they know exactly where to place the components. Installing fenders, windshields, and door panels are done with more precision using robotic vision than regular robotic arms.

Spot and Arc Welding

Gigantic industrial robots that have long arms and higher payloads typically carry out spot welding on heavy panels. Smaller robots, in turn, weld lighter parts such as brackets and mounts. Metal inert gas (MIG) and robotic tungsten inert gas (TIG) welders can position the torch in the exact spot every time. The preservation of quality welding standards is possible due to the speed gap and repeatable arc.

Automotive robots work in collaboration with massive industrial robots on large assembly lines. Robotic handlers and welders must work together to keep the assembly lines on the move. The robot handlers need to put panels at precise locations so the welding robot can carry out the programmed work.

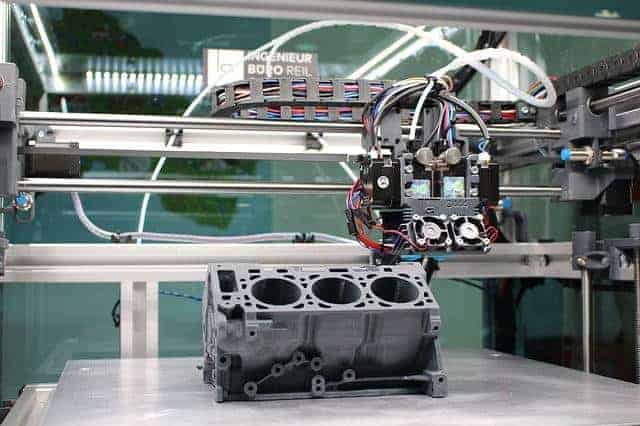

Assembly

In many automotive plants, light robotic arms are used to assemble tiny parts such as pumps and motors at high speeds. Robotic arms carry out other jobs, such as wheel mounting, windshield installing, and screw driving.

Painting, Coating, and Sealing

Automotive painters have a challenging job, which is also very toxic. The shortage of labor makes it hard to find professional and skilled painters. Robotic arms are the perfect stand-ins for the vacuum created by a labor shortage. Robots follow an already programmed course, covering a large area at once and reducing waste. Machines are used for spraying sealants, primers, and adhesives.

Tending Machines and Transferring Parts

The transfer of metal stamps, pouring molten metal in a foundry, and loading and unloading CNC machines is dangerous for humans, but robots can do it effortlessly. Smaller cobots in smaller plants are doing machine tending and other tasks.

Removal of Materials

Robots can follow a convoluted path many times without fail. This ability makes a robot the perfect tool for trimming and cutting tasks. Light robots that have a force-sensing technology work best in these types of functions. Although these robots save time and money, robots often need regular maintenance and servicing. Industrial dust collectors are a common automated machine in industrial processes, and although they require little human interaction, they do need regular Brisbane dust collector servicing. These tasks include cutting fabric, polishing molds, and trimming flash from plastic molds.

Internal Logistics

AMRs (Autonomous mobile robots) and automated vehicles such as forklifts are used in factories to transport raw materials from the storage areas to the factory assembly floor.

Conclusion

Robotics is very much a part of the automotive industry. Without robotics, the industry would not have made the leaps and bounds it has. Technology has played a significant role in the development of automotive and other industries.

Any work that is too dangerous for humans is delegated to the robots. The robots can also work longer hours and are programmed to do repetitive jobs with better precision. The robots are better placed to follow a convoluted path repeatedly do the same task frequently. Human beings cannot do the same without facing health complications. With time, the assembly lines might be fully automated without needing human intervention.